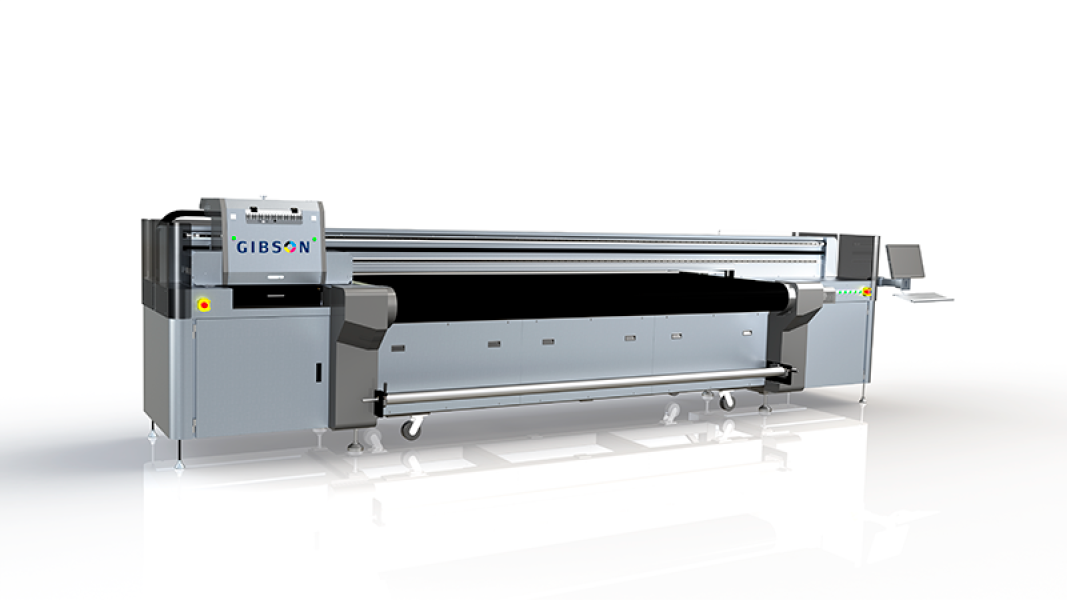

Gibson Image Technology - UV Hybrid

Gibson Image Technology - UV Hybrid Information

Our new range of UV Hybrid Printers capitalises on our years of experience in providing high quality affordable UV Printing Solutions.

The Gibson Hybrid UV Printer range comes in three size options GTH-2000UV – GTH3200UV and the New GTH-1600UV

All the models benefit from a High Quality Enhanced Steel frame with multiple stress relief treatment to reduce distortion & deforming.

Double lead screw technology ensures stable and precise performance.

Optional Linear motor (Not available for GT-H1600UV) offers higher Performance, Accuracy and Repeatability while reducing friction and maintenance.

New Print Board Technology provides additional print options such as 5 Layer Printing for enhanced block out affects.

The Printer benefits from the latest Ricoh GEN6 (MH5320) print head providing greater firing accuracy and smoother images.

As with previous Printers the new range offers the option to start with as little as 2 Print Heads (CMYK) and add additional Print Heads in the field as production increases or requirements change.

All our new Printers are provided with installation and training backed up with 1 years on-site parts and labour warranty.

Features

Automatic Negative Pressure System

Automatic Head Media Height Sensor

3 Litre Bulk Ink Feed

Linear Drive System

LED UV Curing System

Multi Zone Vacuum System

Suck & Blow Vacuum

Anti-Crash Head Protection

Ricoh GEN6 Print Head

Benefits of UV Printing

UV Inks print directly onto a variety of substrates including (Glass, Ceramic, Wood, Metal, Paper, Leather, Wallpaper, Plastics)

UV Inks are long lasting and scratch resistant on most materials so often don’t require laminating. They are suitable for indoor and outdoor applications.

UV Inks are more suitable than other digital printing processes for lower grade substrates.

UV Inks offer White & Varnish Inks for embellishing print products.

UV Inks are cured instantly using UV light so they able to be cut & finished directly after printing.

UV Inks are 99% VOC free.

Hybrid Printer:

A hybrid printer combines the capabilities of different printing technologies into a single device. It can handle both flat materials and roll-fed materials, offering versatility in terms of the types of projects it can handle. Hybrid printers typically have a flatbed table for direct printing on rigid materials (such as boards, glass, or acrylic) and also have the option to load roll-fed materials for flexible media (such as banners, vinyl, or textiles). This makes hybrid printers suitable for a wide range of applications, from signage and graphics to industrial and artistic printing.

Flatbed Printer:

A flatbed printer is designed primarily for printing directly onto rigid, flat materials. It has a flat printing surface or table where the material is placed, and the printing head moves horizontally and vertically to apply ink onto the surface. Flatbed printers are commonly used for printing on materials like wood, glass, metal, ceramics, and other rigid substrates. They are often utilized for applications like signage, promotional materials, and artistic prints.

Roll-to-Roll Printer:

A roll-to-roll printer is designed for printing on flexible materials that come on rolls, such as vinyl, fabric, wallpaper, and banners. The material is fed from a roll onto the printer, and the printing head moves horizontally across the material to apply ink. Roll-to-roll printers are commonly used for large-format applications, such as outdoor banners, vehicle wraps, posters, and textiles. They are well-suited for projects that require continuous printing on flexible media.

In summary, the main differences between these printer types lie in their capabilities and the types of materials they can handle:

Hybrid Printer: Offers both flatbed and roll-to-roll capabilities, making it versatile for various types of materials and applications.

Flatbed Printer: Specialises in printing on rigid, flat materials and is commonly used for signage and artistic applications.

Roll-to-Roll Printer: Specialises in printing on flexible materials that come on rolls and is often used for large-format applications like banners, vehicle wraps, and textiles.